Since the manual was updated in 2022, maritime and port fixed structures can now use the WSCAM for consistent, repeatable inspections. Here's how organisations are using WSCAM with Trendspek for accurate condition assessments.

How WSCAM is used across ports and maritime inspections

Since its introduction in 2014, the WSCAM manual has become widely recognised as a best-practice methodology, providing a consistent framework and guidance on inspecting wharves, piers, jetties, walkways, breakwaters, revetments, embankments, and other fixed assets.

According to the Ports Australia website: "The benefit of using the WSCAM is that inspection results are consistent and repeatable. Without the WSCAM, one might have 10 inspectors assess the same structure and there could be 8 different assessments, depending on their experience and expertise. With example imagery and formulae for calculations, assessments can be made more consistent:

- Expand the scope of the Manual to all port fixed structures excluding buildings.

- Rationalise inspection approaches resulting in a single assessment tool that is flexible for user customisation.

- Provide guidance on a risk/criticality-based approach to determine the frequency of inspections.

- Cover more materials and technology used in assessments."

Here's how it works conducting inspections using WSCAM.

Scope structural assessments

First, you need to consider what kind of structural assessment is needed. WSCAM splits the scoping of structural assessments into seven different common types of inspections and one specialised inspection category:

- Baseline inspections: for new assets

- Periodic visual inspections: for damage or anomalies

- Detailed investigation inspections: in-depth inspections by a team, or a third-party inspector

- Inspections for design: when repurposing an asset for something different, to understand what condition the asset is currently in

- Post-event inspections: if there has been an incident, such as a weather event or a fire, or if the asset is damaged

- Due diligence inspections: for insurance renewals, or if you are looking to sell the asset

- Special purpose inspections: a catch-all of all of the above, but usually for a very specific purpose

Preparing components and material types

After you've completed the scoping, you then must prepare your information. WSCAM recommends listing each component and construction material for each asset type to track their condition over time, ensuring surveyors can follow the same level of detail every time there is an inspection.

Conducting virtual inspections with Trendspek

Trendspek combines cutting-edge technology with advanced photogrammetry to generate 3D models with up to 1mm detail, allowing surveyors a 360 view of the entire maritime asset.

Using a combination of cameras, sensors and GPS, high-resolution data is processed, or "stitched" together, into a 3D Precision Reality Twin, allowing engineers to zoom in, markup and annotate on any defects on-screen without needing to be physically there.

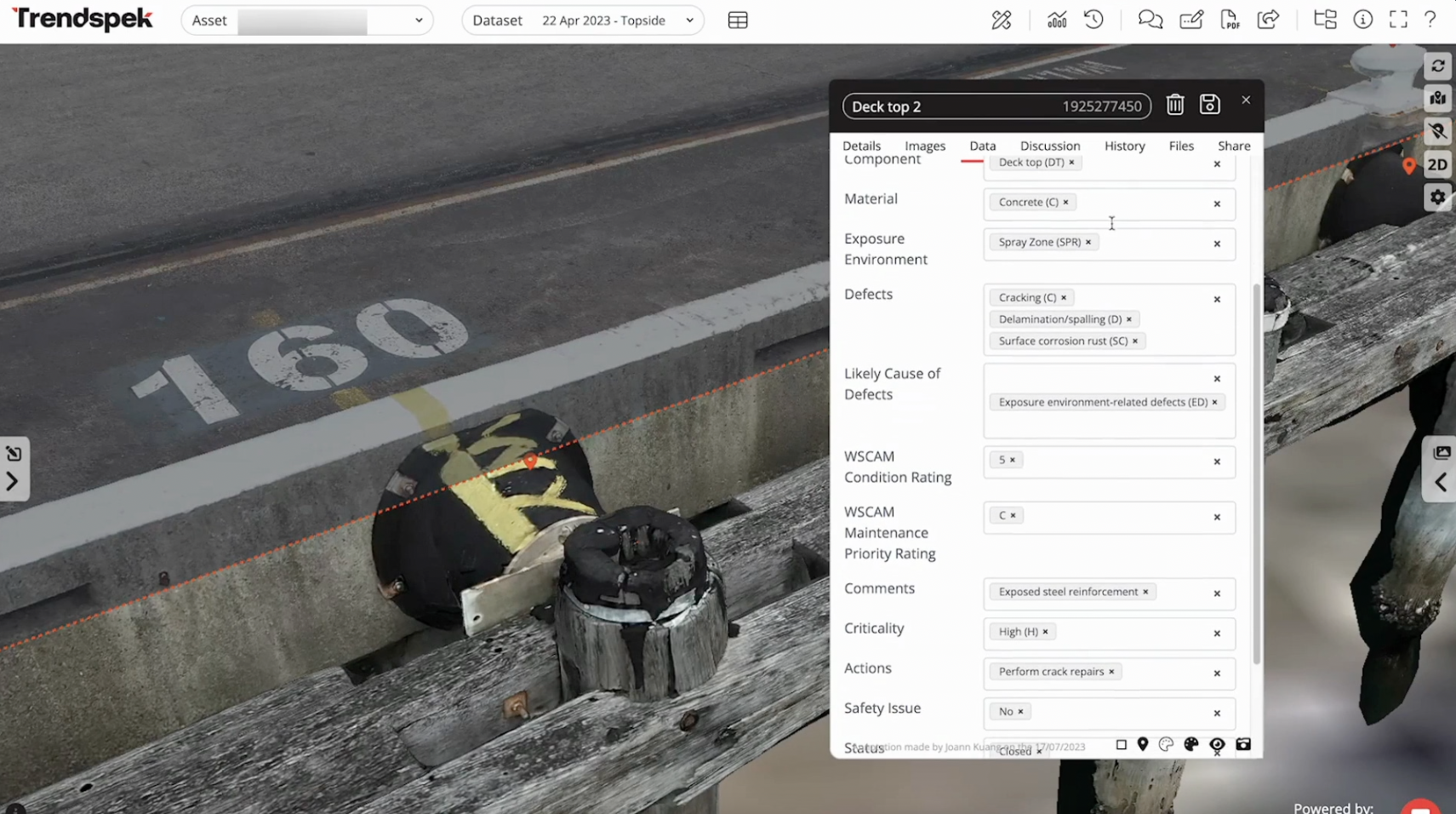

Trendspek’s customisable Annotation Cards allows you to directly annotate onto any defect to assign a WSCSM condition rating, maintenance priority, likely causes, comments and more.

- Condition scaling

- Colour-coded outcomes

- Location

- Component

- Material

- Exposure Environment

- Defects

Key outcomes you can expect

By replacing traditional inspections with Trendspek, inspectors can conduct a comprehensive and accurate assessment of structural condition across a wide portfolio of large assets. This allows for proactive maintenance planning without needing to make repeat site visits, and the continued safe and efficient operation of maritime infrastructure with minimal shutdown periods.

- A very thorough, accurate record of condition aligned to WSCAM and any custom reporting criteria.

- Complete context in 3D, ability to virtually 'fly around' to any place on the wharf structure digitally

- No more ambiguity about where a defect is located.

- Easily share and communicate with contractors and other stakeholders

- Easily repeat to monitor trends, compare models directly side by side to assess trends or deterioration